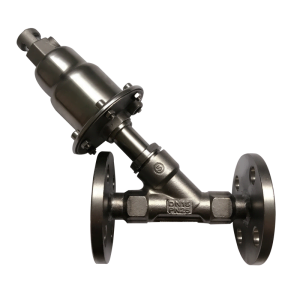

Key features.

- Drive: Pneumatic piston drive ensures precise control.

- Body Configuration: Two-position, two-way valve with Y-angle design to minimize flow resistance.

- Flow capacity: High flow rate due to flow channel optimization and minimum pressure loss.

- Temperature range: Suitable for high temperature applications up to [180]°C.

- Pressure Rating: Capable of withstanding pressures up to [15] Bar.

- Material: [Stainless steel body, PTFE seals] to ensure durability and compatibility with a wide range of media.

- Connection type: [Flange connection] for easy installation.

- Size Options: Available from [DN15

~DN15

DN100] to provide versatility for different piping systems. - Certification: [ISO9001].

Application Scenario: Suitable for [Air Separation Processing, Printing and Dyeing Equipment, Industrial Washing Machines, Mould Temperature Machines], [Flange] Angle Seat Valves ensure a reliable and efficient flow control solution.

Strengths.

- Energy saving: Low energy consumption due to efficient design.

- Long service life: Designed for durability and long-term performance.

- Maintenance: Maintenance-free, can be retrofitted with a variety of accessories for displaying position, travel limiters or for manual emergency operation.

Customization Options: We offer customization options to meet your specific needs. Please contact us to discuss how we can customize [flanged] angle seat valves for your application.