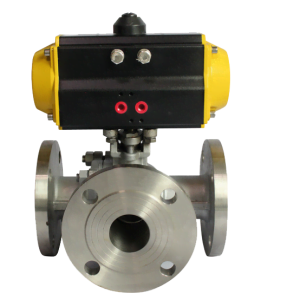

Electric quick release ball valve Q981F-16P

Electric flange ball valve adopts two-piece floating ball structure, full bore design to meet the requirements of pipeline clearing, with large flow capacity. The valve body as a whole adopts silicone sol technology casting, smooth surface without burr, easy processing. This valve is applied to pipeline cut off or connect the medium in the pipeline, suitable for two cut off or regulation of the occasion. Can be used for water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media respectively. Widely used in papermaking, petroleum, chemical, metallurgy, electric power, water treatment, environmental protection, petroleum, light industry and other industries in the automation control.

Electric flange ball valves are divided into two types of action: switching type and regulating type. Switching type has only fully open and fully closed limit position, after receiving appropriate instructions, the actuator drives the valve to fully open and fully closed position. The regulating type is controlled by the intelligent control module integrated in the electric actuator to receive control signals to realize the angle control of the valve, which has the functions of digital setting, digital calibration, high precision, self-diagnosis, multi-functionality and so on, and there is no need for an external positioner. SKF’s electric actuators are equipped with hand-operated devices, such as on-site control of power failure, you can directly insert the handle into the manual operation port to drive the valve. The electric actuator also has over-torque protection, heating and dehumidification optional functions for customers to choose.

Compared with other valves, electric flange ball valves have some advantages as follows:

- Fluid resistance is small, the ball valve is the smallest fluid resistance of all valve types, even the reduced ball valve, its fluid resistance is quite small.

- The switch is quick and convenient, as long as the valve stem rotates 90°, the ball valve completes the full open or full close action, it is easy to realize the rapid opening and closing.

- Good sealing performance. Ball valve seat seal ring is generally made of PTFE and other elastic materials, easy to ensure sealing, and the sealing force of the ball valve increases with the increase in media pressure.

- Valve stem sealing is reliable. Ball valve opening and closing the valve stem only for rotary movement, so the stem packing seal is not easy to be destroyed, and the sealing force of the stem inverted seal with the increase in media pressure.

- The opening and closing of the ball valve only do 90 ° rotation, so it is easy to realize automation control and remote control, the ball valve can be equipped with pneumatic device, electric device, hydraulic device, gas-liquid linkage device or electro-hydraulic linkage device.

- Ball valve channel is flat and smooth, not easy to deposit media, can be pipeline through the ball.